-

Ultra-high…

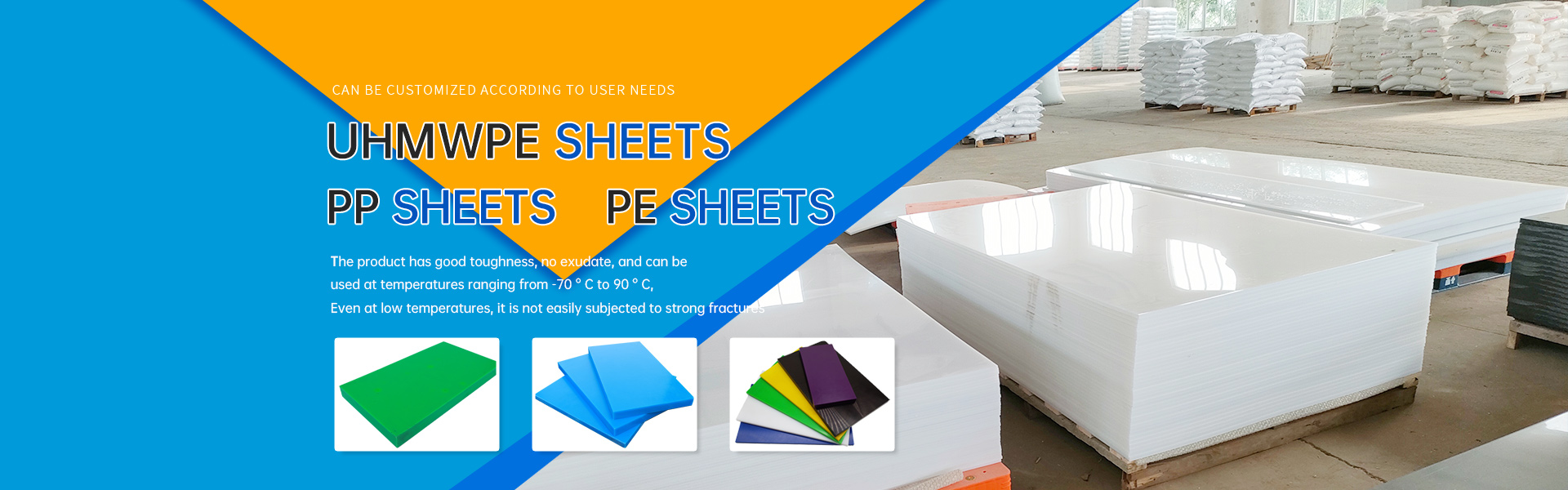

Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic engineering plastic with excellent comprehensive properties. It is usually composed of ultra-high molecular weight polyethylene powder with an average molecular weight of more than 1.5 million and appropriate additives (such as glass beads, glass fiber, mica, Talcum powder, etc. can improve hardness, stiffness and temperature resistance; molybdenum disulfide, silicone oil and special wax can reduce the friction factor, thereby further improving self-lubrication; carbon black or metal powder can improve antistatic properties, electrical conductivity and heat transfer. ; Flame retardant or masterbatch, boron carbide powder and lead powder, etc.) are filled, blended and modified, and then sintered and pressed under high temperature and high pressure. Its basic characteristics are wear resistance, impact resistance, self-lubrication, corrosion resistance, and With comprehensive properties such as impact energy absorption, low temperature resistance, hygienic and non-toxic, not easy to adhere, not easy to absorb water, and low density, it is widely used in Conveying, food, papermaking, textiles, construction, chemical industry, coal mines, power plants, ports, sports, medical care, etc. industry.

-

Ultra-high…

Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic engineering plastic with excellent comprehensive properties. It is usually composed of ultra-high molecular weight polyethylene powder with an average molecular weight of more than 1.5 million and appropriate additives (such as glass beads, glass fiber, mica, Talcum powder, etc. can improve hardness, stiffness and temperature resistance; molybdenum disulfide, silicone oil and special wax can reduce the friction factor, thereby further improving self-lubrication; carbon black or metal powder can improve antistatic properties, electrical conductivity and heat transfer. ; Flame retardant or masterbatch, boron carbide powder and lead powder, etc.) are filled, blended and modified, and then sintered and pressed under high temperature and high pressure. Its basic characteristics are wear resistance, impact resistance, self-lubrication, corrosion resistance, and With comprehensive properties such as impact energy absorption, low temperature resistance, hygienic and non-toxic, not easy to adhere, not easy to absorb water, and low density, it is widely used in Conveying, food, papermaking, textiles, construction, chemical industry, coal mines, power plants, ports, sports, medical care, etc. industry.

-

Ultra-high…

Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic engineering plastic with excellent comprehensive properties. It is usually composed of ultra-high molecular weight polyethylene powder with an average molecular weight of more than 1.5 million and appropriate additives (such as glass beads, glass fiber, mica, Talcum powder, etc. can improve hardness, stiffness and temperature resistance; molybdenum disulfide, silicone oil and special wax can reduce the friction factor, thereby further improving self-lubrication; carbon black or metal powder can improve antistatic properties, electrical conductivity and heat transfer. ; Flame retardant or masterbatch, boron carbide powder and lead powder, etc.) are filled, blended and modified, and then sintered and pressed under high temperature and high pressure. Its basic characteristics are wear resistance, impact resistance, self-lubrication, corrosion resistance, and With comprehensive properties such as impact energy absorption, low temperature resistance, hygienic and non-toxic, not easy to adhere, not easy to absorb water, and low density, it is widely used in Conveying, food, papermaking, textiles, construction, chemical industry, coal mines, power plants, ports, sports, medical care, etc. industry.

-

Ultra-high…

Ultra-high molecular weight polyethylene (UHMWPE) is a thermoplastic engineering plastic with excellent comprehensive properties. It is usually composed of ultra-high molecular weight polyethylene powder with an average molecular weight of more than 1.5 million and appropriate additives (such as glass beads, glass fiber, mica, Talcum powder, etc. can improve hardness, stiffness and temperature resistance; molybdenum disulfide, silicone oil and special wax can reduce the friction factor, thereby further improving self-lubrication; carbon black or metal powder can improve antistatic properties, electrical conductivity and heat transfer. ; Flame retardant or masterbatch, boron carbide powder and lead powder, etc.) are filled, blended and modified, and then sintered and pressed under high temperature and high pressure. Its basic characteristics are wear resistance, impact resistance, self-lubrication, corrosion resistance, and With comprehensive properties such as impact energy absorption, low temperature resistance, hygienic and non-toxic, not easy to adhere, not easy to absorb water, and low density, it is widely used in Conveying, food, papermaking, textiles, construction, chemical industry, coal mines, power plants, ports, sports, medical care, etc. industry.

Follow us

Scan and follow us