-

PE sheet

PE sheet (polyethylene sheet) is a highly crystalline, non-polar thermoplastic resin whose surface can be filled, embossed, or frosted. PE can be modified and customized by adding glass fiber, metal additives or thermoplastic rubber to meet unique application requirements, such as glass fiber reinforced PE boards, PE modified boards, and PE flame retardant boards.

Regular size: 1000×2000; 1220×2440; 1300×2000; 1500×3000; 2000×3000; Width: up to 2m ;Thickness: 3-25mm;Length: Can be customized according to user requirements

Color: milky white translucent, black, blue, etc.

Features: Small density, light weight, low cost and long life; Good electrical insulation; Good resistance to chemical corrosion, especially solvents and acids and alkalis. It is resistant to low temperatures and has excellent toughness and elastic strength at low temperatures. Good wear resistance; Easy to weld and process; Non-toxic and harmless, can come into contact with food.

Applications: chopping boards, cutting boards, gears, rollers, bearings, wear-resistant linings, conveying equipment accessories, medical instrument components, seals, cutting boards, sliding profiles. Widely used in chemical industry, machinery, chemical industry, electric power, clothing, packaging, food and other industries. -

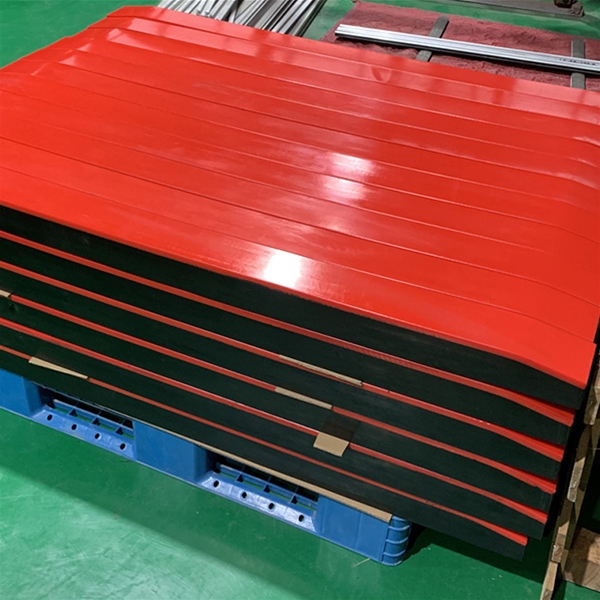

UHMW-PE im…

Impact Bars are composed of rubber, metal frame (aluminum/steel), UHMW-PE plate using special thermal vulcanization. It is mainly used for conveyor loading points or transfer points, efficiently absorb and alleviate the impact of loading and help eliminate spillage and scattering of the products.

It is used for belt conveyor systems in the majority of thermal power plants, building materials, steel, ports and mining industries.

Features:

UHMWPE surface with extremely low coefficient of friction will reduce the abrasion.

Available in di?erent color and grades.

Shock absorbing rubber can absorb maximal impact of materials.

“T-slot” extruded metal construction allows for easier installation and disassembly.

Thermal vulcanization insures an efficient and reliable joining between the layers.

Also available in Fire Resistant and Anti-Static (FRAS) impact bars which complied with MDG3608, AS1334.10 and MT 113-1995 standards. Suitable for underground application.Download product brochure

-

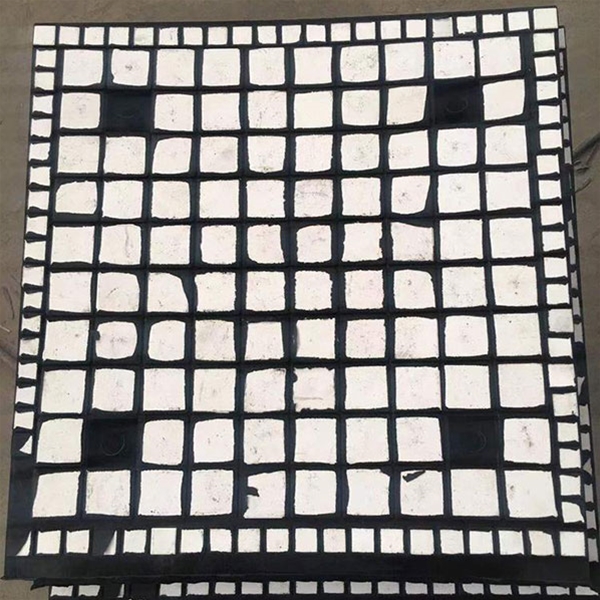

UHMW-PE im…

Impact Bars are composed of rubber, metal frame (aluminum/steel), UHMW-PE plate using special thermal vulcanization. It is mainly used for conveyor loading points or transfer points, efficiently absorb and alleviate the impact of loading and help eliminate spillage and scattering of the products.

It is used for belt conveyor systems in the majority of thermal power plants, building materials, steel, ports and mining industries.

Features:

UHMWPE surface with extremely low coefficient of friction will reduce the abrasion.

Available in di?erent color and grades.

Shock absorbing rubber can absorb maximal impact of materials.

“T-slot” extruded metal construction allows for easier installation and disassembly.

Thermal vulcanization insures an efficient and reliable joining between the layers.

Also available in Fire Resistant and Anti-Static (FRAS) impact bars which complied with MDG3608, AS1334.10 and MT 113-1995 standards. Suitable for underground application.Download product brochure

-

ceramic li…

-

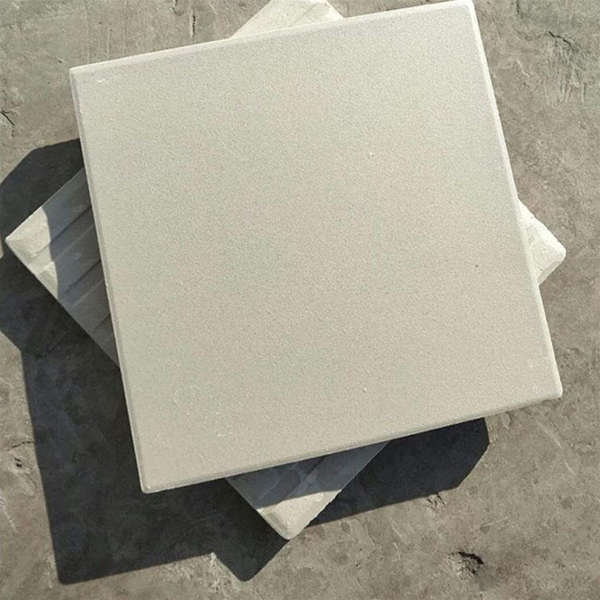

Calendered…

Calendered microcrystalline plate is a new type of silicate crystalline material and one of the achievements in the field of glass technology. It is a microcrystalline material made from blast furnace slag, basalt, and diabase as its main raw materials, with the addition of silica sand and an appropriate amount of crystal nucleating agent, and through melting, molding, and crystallization. Microcrystalline cast stone not only has wear resistance and corrosion resistance, but also has high pressure resistance and impact resistance. The thickness of the rolled microcrystalline plate can be as thin as 10mm, with a smooth appearance and uniform thickness. Because microcrystalline cast stone slabs are thinner than ordinary cast stone slabs, they are easier to install and construct. The load-bearing weight of the equipment is reduced, and the service life and maintenance cycle of the equipment are greatly extended.

Main colors of calendered microcrystalline plates: pearl black, agate red, ivory white

-

Cast Basal…

Cast basalt is a kind of silicate crystalline material after producing and processing, it made of natural rock (basalt, diabase and other basite) or some industrial waste as the main raw materials, by melting, casting, crystallization, annealing and other processes. Cast basalt have an excellent performance of high abrasive and high corrosion resistance. Cast basalt products mainly include cast basalt tile, cast basalt pipe, cast basalt lined steel pipe, clamp cast basalt pipe, cast basalt wear-resistant slip joints, cast basalt wear-resistant valves, cast basalt powder and various wear-resistant corrosion-resistant cement which use cast basalt powder as raw material. Cast basalt products have been widely used in industrial sectors which have serious wear and corrosion of parts and equipment, such as electric power, mining, metallurgy, coal, chemicals, construction and so on. Cast basalt is an indispensable non-metallic industrial new material in the development of modern industry.

-

Cast Basal…

Cast basalt is a kind of silicate crystalline material after producing and processing, it made of natural rock (basalt, diabase and other basite) or some industrial waste as the main raw materials, by melting, casting, crystallization, annealing and other processes. Cast basalt have an excellent performance of high abrasive and high corrosion resistance. Cast basalt products mainly include cast basalt tile, cast basalt pipe, cast basalt lined steel pipe, clamp cast basalt pipe, cast basalt wear-resistant slip joints, cast basalt wear-resistant valves, cast basalt powder and various wear-resistant corrosion-resistant cement which use cast basalt powder as raw material. Cast basalt products have been widely used in industrial sectors which have serious wear and corrosion of parts and equipment, such as electric power, mining, metallurgy, coal, chemicals, construction and so on. Cast basalt is an indispensable non-metallic industrial new material in the development of modern industry.

Follow us

Scan and follow us