-

Home

- About us

- Products

-

Concrete Protection Liners

-

Outrigger pads

-

Synthetic ice rink tiles

-

Drag flights

-

Marine fender panels

-

Dock bumpers

-

Ground protection mats

-

Special-shaped parts

-

UHMWPE sheets

-

PP sheets

-

PE sheets

-

Impact bar

-

Ceramic liner

-

Guide rails

-

Casing End seals

-

Casing spacer

- News

- Company scene

Classify

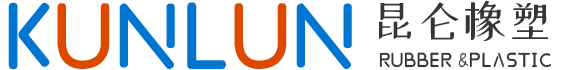

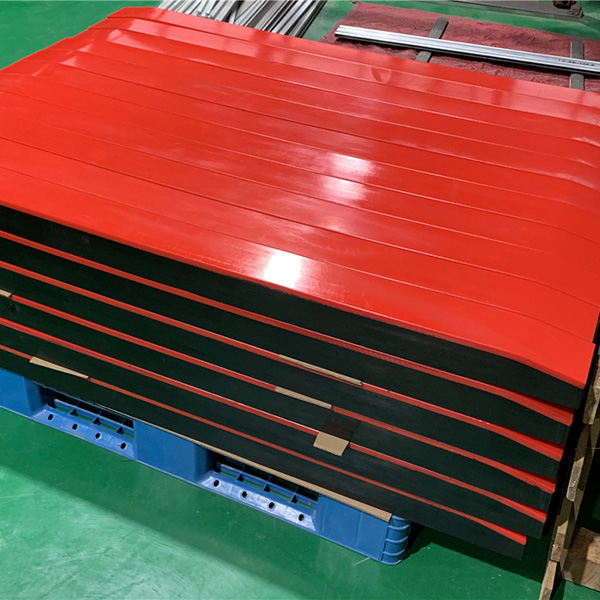

ClassifyUHMW-PE impact bars

- Type:Impact bar

- Code:

-

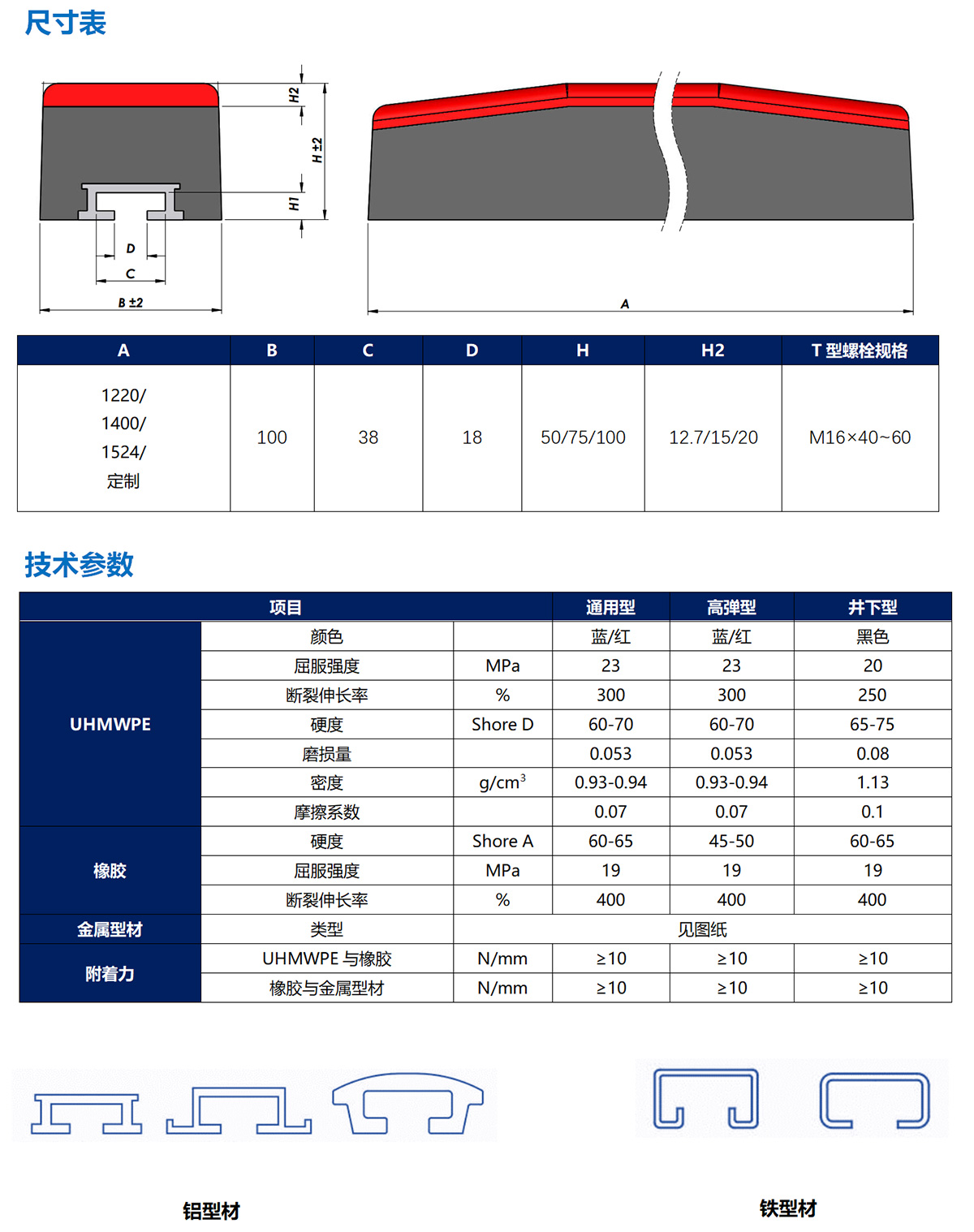

Impact Bars are composed of rubber, metal frame (aluminum/steel), UHMW-PE plate using special thermal vulcanization. It is mainly used for conveyor loading points or transfer points, efficiently absorb and alleviate the impact of loading and help eliminate spillage and scattering of the products.

It is used for belt conveyor systems in the majority of thermal power plants, building materials, steel, ports and mining industries.

Features:

UHMWPE surface with extremely low coefficient of friction will reduce the abrasion.

Available in di?erent color and grades.

Shock absorbing rubber can absorb maximal impact of materials.

“T-slot” extruded metal construction allows for easier installation and disassembly.

Thermal vulcanization insures an efficient and reliable joining between the layers.

Also available in Fire Resistant and Anti-Static (FRAS) impact bars which complied with MDG3608, AS1334.10 and MT 113-1995 standards. Suitable for underground application.Download product brochure

- Product Description

Copyright @ 2023 . All Rights Reserved 極速互聯(lián) ICP:魯ICP備2023031823號-1 - About us